Conical Screw Mixers

Conical Screw Mixers are used as mixers, blenders, homogenizers, reaction vessels, vacuum dryers and live storage hoppers. See Jaygo’s options

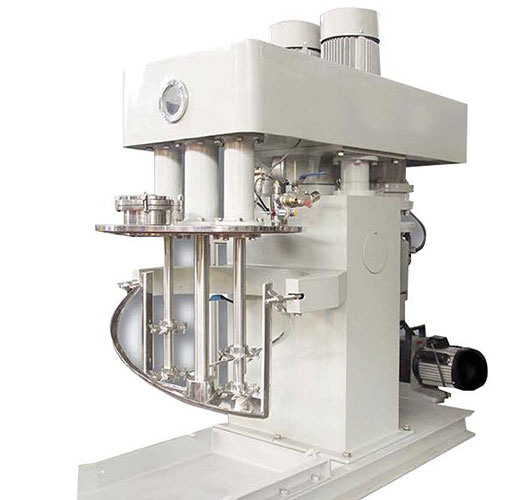

Double Planetary Mixers

Double Planetary & Multi-Shaft Mixers are typically used in kneading mixing, blending, dispersing, and drying applications. These mixers can be used with products of low to high viscosity, for a wide range of industries. See Jaygo’s options

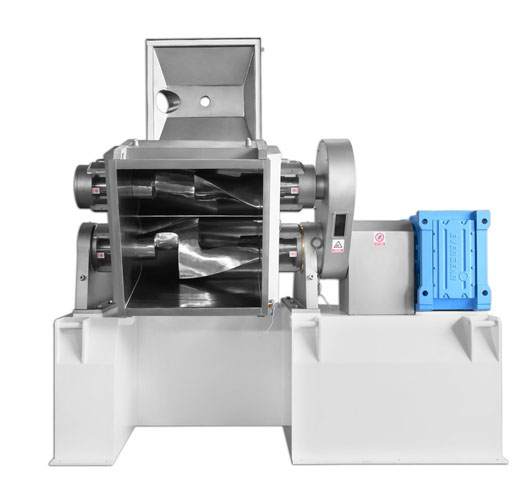

Double Arm Mixers

Double Arm Mixers and Mixer Extruders are designed to mix, blend, disperse, and knead very high viscosity products. Double Arm Mixers include two mixing blades, normally “Sigma” shaped, but also available in “Dispersion”, or “Double Nobbin” shapes. See Jaygo’s options

Double Arm Mixer Extruders

Mixer Extruders include an extrusion screw located in the bottom of the mixing chamber that operates in reverse during the mixing cycle, aiding the mixing blades slightly. The extrusion screw direction is then reversed after mixing, allowing the extrusion screw to discharge the product. Various shaped dies may be added to the end of the extrusion barrel, enhancing the versatility of the equipment. See Jaygo’s options

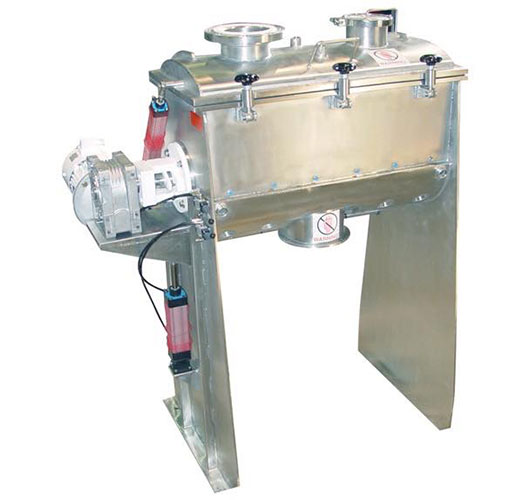

Double Ribbon & Paddle Blenders

Double Ribbon Blenders are a horizontal mixer/blender for a wide variety of dry, liquid or slurried products. These versatile mixers are efficient and economical. Designs are available for both the Chemical industry and also the sanitary requirements of the Food and Pharmaceutical industries. USDA and 3A DAIRY accepted designs. See Jaygo’s options

Vee & Double Cone Blenders

Vee Blenders and Double Cone Blenders provide gentle high-flow mixing for solids/solids blends Designed to mix in a proportion of up to 1:100.000 with the possibility of using an intensifier bar to enhance the mixture, and solids/liquids in powder or granulate form with different specific weights. See Jaygo’s options

Multi-Shaft Mixers

Multi-Shaft Mixers are robust, heavy-duty mixing machines designed for the production of a multitude of products. Customers can select equipment from a variety of agitator shapes and sizes designed to emulsify, disperse, and mix all types of products. Free flowing or wet powders can also be mixed, granulated, and dried utilizing various blade options. Typical product viscosities range from 1 cps to approximately 750,000 centipoises. See Jaygo’s options

Plough & Turbulent Blenders

Plough & Turbulent Blenders can be utilized for blending dry, powdery, granular, fibrous, and moist solids and liquids together with pasty products up to and including highly viscous masses. Plough & Turbulent Blenders can be used for numerous processes, including compounding, fine mixing, dispersing, suspending, emulsifying, deaerating, tempering, accelerating chemical or physical reactions, granulating, breaking down agglomerates, etc. See Jaygo’s options

Liquid Vacuum Deaerators

Liquid Vacuum Deaerators for continuous automatic removal of air and other gases from liquid, viscous, and pasty products. Processing of liquid products often incorporates air and unwanted gases into the product. These gases normally cause problems such as oxidation, discoloration, inconsistency and filling difficulties. Jaygo’s liquid deaeration plants have been developed to alleviate these problems by removing entrapped gases efficiently and economically.

See Jaygo’s options

Sampling Valves

Sampling valves allow taking samples of chemicals or pharmaceuticals (liquids, powders, suspensions) from process vessels and reactors.

See Jaygo’s options

Ball Segment Valves

Ball Segment Valves are unique in that they can handle both liquid and dry abrasive products from fine powder to course abrasives. Bal Segment Valves have an opening where materials cannot build up, accumulate, or be captured within the valve body.

See Jaygo’s options

Pressure Vessel Clamps

Pressure vessels clamps are designed to work with ASME code pressure vessels and non-code vessels. Our quick release pressure vessel clamps eliminate the need to drill holes in the flange of the vessel, eliminating the stress concentrations at the bolt holes.

See Jaygo’s options

Discharge Press

Discharge Presses are used for highly viscous products and are accurately packed by the unit’s volumetric proportioner. Portion sizes are controlled, readily adjustable, and protected from over or under filling. The hydraulic operated press easily packs your product into cans or cartridges. See Jaygo’s options

Altern-Mill – Batch Mills

Altern Mill – Batch Mills are uniquely designed, offering a special grinding chamber and disperser/mill combination for “Super-Fine” grinding of high value cosmetics, pharmaceuticals, and paints. This allows for simple cleaning between formulations, saving time and money. The Mill can be fabricated in stainless steel or special steel alloys. See Jaygo’s options

Grinding Media

Grinding media for use in both wet and dry grinding, it’s a perfect fit for many industries, including Cosmetic, Optical, Dental, Medical, Paints & Coatings and Pharmaceutical. See Jaygo’s options

Used Process Equipment

Our Used Process Equipment includes refurbished process equipment such as mixers, blenders, deaerators, strainers, dryers, and much more. We not only refurbish our own product lines but can repair and rebuild competitors’ machines as well. See Jaygo’s options

Rebuilt & Refurbished Mixers

Your equipment will be disassembled, cleaned and inspected. Worn or damaged parts are replaced or restored to original specifications. The reassembled equipment is then thoroughly tested before it is returned to you. See Jaygo’s options

Equipment Rental & Testing Facilities

Our equipment rental program makes quality equipment available to customers that do not have the need or capitol to purchase equipment. See Jaygo’s options

Spare Parts

Comprehensive process equipment parts and service on our extensive line of equipment as well as our competitors’ equipment are available. See Jaygo’s options

Industrial Mixers and Blenders for Every Application

Jaygo Incorporated is a leading U.S. manufacturer and supplier of industrial mixers, blenders, and process equipment. Since 1971, we’ve been delivering high-performance mixing solutions to industries across the country—from small businesses to Fortune 500 companies.

Located in New Jersey, Jaygo specializes in custom mixing equipment, used and refurbished process machinery, and comprehensive repair services. Our mission is to help your business improve efficiency, reduce downtime, and stay competitive in today’s demanding markets.

Our Industrial Equipment Solutions

Explore our full range of process equipment:

- Industrial Mixers & Blenders

High-efficiency mixing equipment for chemical, pharmaceutical, food, and cosmetic industries. - Custom Process Equipment Design

Tailored solutions to meet your exact production requirements. - Used, Rebuilt & Refurbished Equipment

Cost-effective alternatives with guaranteed performance and reliability. - Spare Parts & Replacement Components

OEM parts to keep your equipment running at peak performance. - Equipment Rentals

Short-term and long-term rental options to test equipment in your facility. - Repair & Maintenance Services

Expert service for both domestic and international process equipment.

Why Choose Jaygo?

- Over 50 years of experience in industrial mixing and blending equipment

- Custom engineering and fabrication capabilities

- Full-service support from design to installation

- Trusted by manufacturers across the USA

- Fast turnaround on parts, service, and rentals

Contact Jaygo Today

Ready to upgrade your process equipment or need expert support?

Get in touch with our team today:

- Based in New Jersey – Serving Nationwide

- Call: 908-688-3600

- Toll-Free: 1-888-815-2946

- Or fill out our online inquiry form