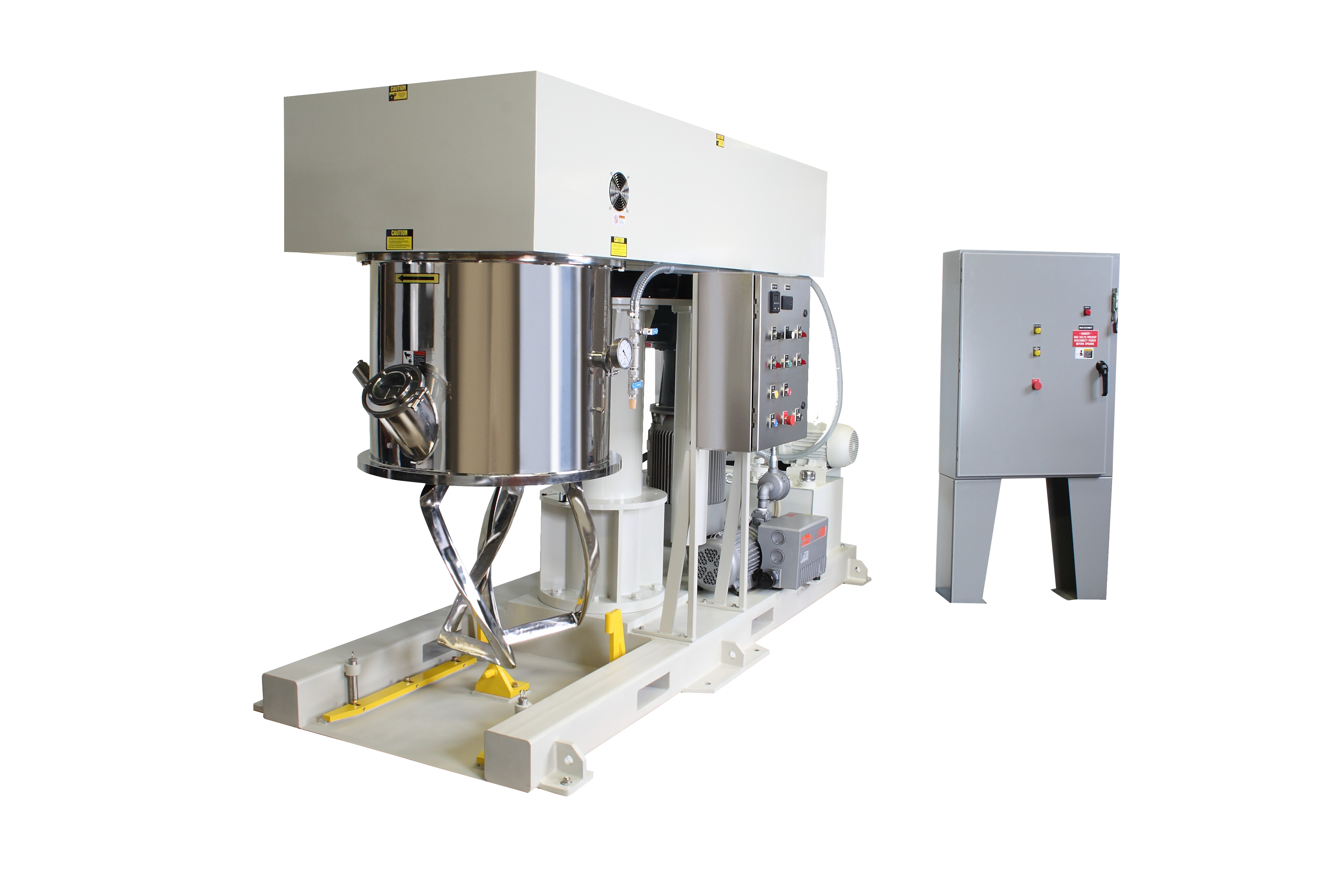

Double Planetary Mixers

Jaygo’s Double Planetary & Multi-Shaft Mixers are typically used in kneading mixing, blending, dispersing, and drying applications. These mixers can be used with products of low to high viscosity, for a wide range of industries. Typical product viscosities range from 1 cps to approximately 2,000,000 centipoises. Jaygo Double Planetary and Multi-Shaft Kneader Mixers are designed to operate at high vacuum and feature jacketed construction (including insulation and sheathing), on the vessel sidewalls and bottom. Typical heating and cooling mediums include oil, water, steam, or glycol. The Planetary Mixers are designed to maintain working temperatures between 34 and 355°F.

Blade options include Quarter-Twist, Rectangular, Vertical Shaft, and Butterfly configurations, with optional High Speed Disperser Shaft and Blade assemblies utilizing a second drive.

Methods of product discharge include pressing out the mixture with a Hydraulic Discharge Press, incorporation of a bottom discharge valve (ball, plug), or tilting the bowl to scoop or pour the contents out.

Planetary Mixers can be sized for laboratory use in 1, 5, and 10 liter volumes; pilot production with 20, 30, and 50 liter volumes; or full production with a 75 to 3000 liter volume range.