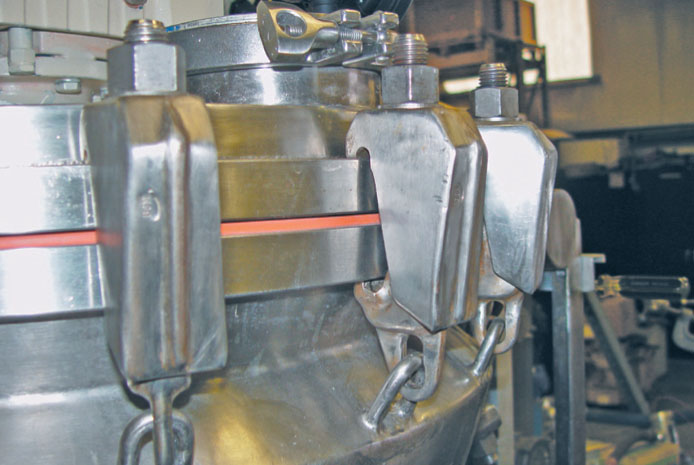

Pressure Vessel Clamps

The best way to clamp a pressure vessel, manway or pipe

Jaygo carries a full line of pressure vessel clamps or manway clamps designed to work with ASME code pressure vessels. Our quick release pressure vessel clamps eliminate the need to drill holes in the flange of the vessel, eliminating the stress concentrations at the bolt holes. Eliminating these stresses allows the flange to be thinner while providing the same closing strength.

These clamps are designed for compliance with all applicable ASME section VIII safety requirements and are approved for use by all major insurance companies. Not only do our quick release clamps save time and money in the design and fabrication of the vessel, they drastically reduce the time required to open and close the vessel, providing continual labor savings. At Jaygo, we specialize in customized solutions that help our clients increase safety and efficiency in their processing operations.

Our quick release pressure clamps are ideally suited for reactor vessels, pressure vessels, vacuum vessels, pressurized filter housings, mix vessels, Nutsche filters, centrifuges, and manways.

Fastener Options

- Hex head Nut

- Wing Nut

- Cap Nut

- T-Handle

Coating Options

- Zinc Plating

- Vecalit Plating

- Electropolishing

- Pickling & Passivating

We operate a special test lab specifically for testing clamps by traceability number and can assist in choosing the appropriate size and strength of clamp for a given application. We carry stock on our most popular clamps to provide customers with expedited turnaround of the most commonly ordered clamp sizes and configurations.

manway clamps also known as Segmented Screw Clamp

Now in stock the following models:

- M12-L-B8M

- M12-L-B7

- M16-K-B8M

- M16-K-B7

- M16-L-B8M

- M16-L-B7

This quick-release pressure vessel clamp system is the most practical and widely used means of positively securing flanges on pressure vessels in processing plants. The clamps replace conventional swing bolts and typically provide substantial saving over stud bolts on any vessel or processing equipment requiring even occasional opening. A wide range of sizes and types are available, including special versions with limited swing, downward release, reversing swing, etc…

The segmented screw clamp can be modified to fit your processing needs.

SAVE TIME AND MONEY

- REDUCE LABOR TIME IN HALF or less as compared with standard nut and bolt

- NO DRILLED FLANGES – Closing force acts near vessel wall

LESS Material (Narrower & shallower flange section) - LESS Preparatory Work

- LESS Machining (drilling, rolling, etc…)

- FEWER closing screw clamps than standard nut and bolt

- QUICKER RELEASE with fewer turns of each nut

- SAFER – Eliminates dangers created by missing nuts and bolts

Available Materials:

- Type B7, steel ASTM SA 193-B7 (4142 Equivalent)

- Type A4, stainless steel, Mat. no. 1.4571, (316Ti Equivalent)

- Type B8M, stainless steel ASTM 193-B8M, (316Ti Equivalent)

The Clamp model number is the Item# from the list below, plus: B7 or A4/B8M For example: M16-L-A4/B8M