The New Jersey Business & Industry Association and New Jersey Business Magazine are proud to honor eight outstanding manufacturers across the state as part of our 5th annual Manufacturing Awards. Representing a wide range of industries and business sizes, these companies exemplify the strength, innovation, and economic impact of New Jersey’s manufacturing sector. Each awardee showcases a commitment to quality, problem-solving, and the advancement of products that touch lives locally and around the world.

Among this year’s honorees is Jaygo, Inc.:

Jaygo, Inc.

Jason Hayday, President and CEO

www.jaygoinc.com

Jaygo, Inc., established in 1971, is a leading manufacturer and distributor of high-quality process equipment tailored for the chemical, pharmaceutical, food, and cosmetics industries. Over the years, Jaygo has earned a reputation for engineering innovative solutions that include industrial mixers, blenders, dryers, specialty valves, pressure vessel clamps, and custom glass grinding media.

Operating from its headquarters in Randolph, with strategic partnerships across Europe and Asia, Jaygo has built a global presence. The company employs a dedicated team of skilled professionals, with staffing levels adjusted to meet the demands of each project.

Jaygo’s equipment serves a vast array of applications, demonstrating unparalleled versatility. From chewing gum to silicones, laundry detergents to soup mixes, and snack bars to chemical catalysts, Jaygo’s solutions touch countless products in industries worldwide. Regardless of the challenge, Jaygo delivers precision-engineered equipment to meet the unique mixing, blending, and processing needs of its diverse clientele.

To learn more about how Jaygo can support your production needs with precision-engineered solutions, visit www.jaygoinc.com or contact their team directly to start a conversation.

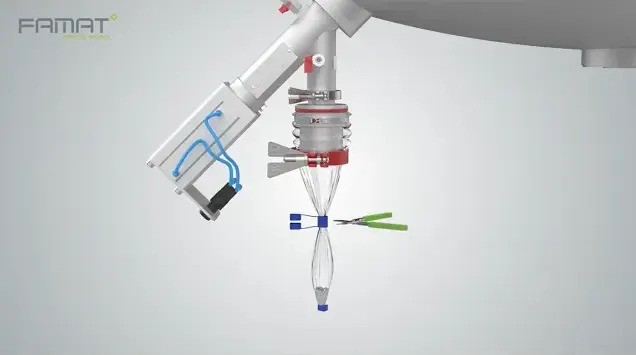

Sanitary Mixer/Disperser for High Viscosity Products

Jaygo recently shipped its new Sanitary Double Planetary Mixer/Disperser model TDPMD-10 to a manufacturer of medical devices. This highly versatile equipment is designed to mix low to high viscosity liquids, slurries, pastes, ointments, suspensions, and gels, in batches from 2.5-10 liters. All product contact parts are highly polished 316L Stainless Steel, all other components are enclosed in a stainless housing with access doors. The equipment includes fan-less variable speed Servo Motor drives, a heating/cooling system, vacuum system, hydraulic system, an Allen-Bradley Touch Screen on swing arm, and Allen-Bradley CompactLogix PLC. Sections of the mixer come apart easily by hand for cleaning. A jacketed mix bowl allows for process heating and cooling. The integrated vacuum pump provides for processing under high vacuum.

Jaygo is located in Randolph, NJ, west of New York City and approximately 45 minutes from Newark Airport.

Please contact Jason Hayday (President), for more information.

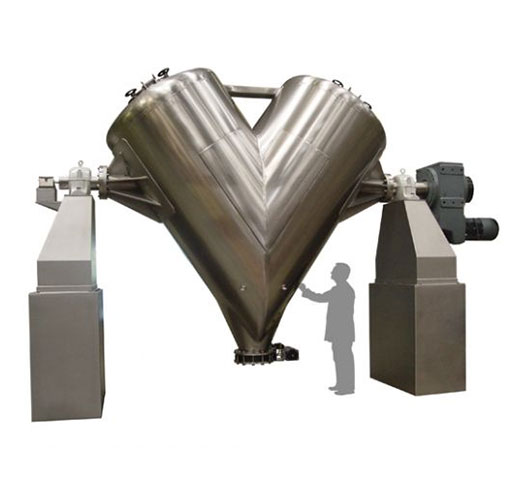

Jaygo recently shipped a sanitary Vee Blender to blend various powder ingredients for the production of vitamins and supplements. The unique design of Jaygo’s Vee Blender provided important benefits to the customer including increased blender shell strength and enhanced discharge and cleanability. The 8000 liter blender was constructed in 316 Stainless Steel and included a pneumatically actuated discharge valve with inflatable seat, radio frequency proximity switches for the loading ports, and a radio frequency level probe to monitor fill level when cleaning. The blender was positioned for loading or cleaning through the use of an encoder.

Jaygo Vee and Double Cone Blenders & Dryers can be supplied from 8 to 8000 liters and include jackets for heating/cooling, intensifier bars for deagglomeration and liquid addition, vacuum outlet with filter housing, as well as various types of charging and discharging systems. Click here for more Information.

Double Arm Mixer with Overlapping Blades

Jaygo recently shipped a 300 gallon Double Arm Mixer with Overlapping Blades to be used for drying of specialty metal powders. Due to the extreme weight and doughy consistency of the product as it is dried, the heavy duty nature of this equipment combined with the unique overlapping blade design provides just the right amount of strength, power, shear, and energy to mix, blend, and dry this difficult-to-handle product. The equipment included jacketing for product heating, vacuum shaft seals, and a special tilt system to handle the extreme weight of the batch and machine.

Machines are also available with other styles of mixing blades (including internally cored blades for heating) and non-Overlapping designs. Click here for more Information.