Double Planetary Mixers

At Jaygo, Inc. our Double Planetary Mixers are engineered to deliver exceptional mixing performance for a wide range of applications. Known for their robust design and precision, these mixers are ideal for industries that require high-efficiency blending and consistent results.

What is a Double Planetary Mixer?

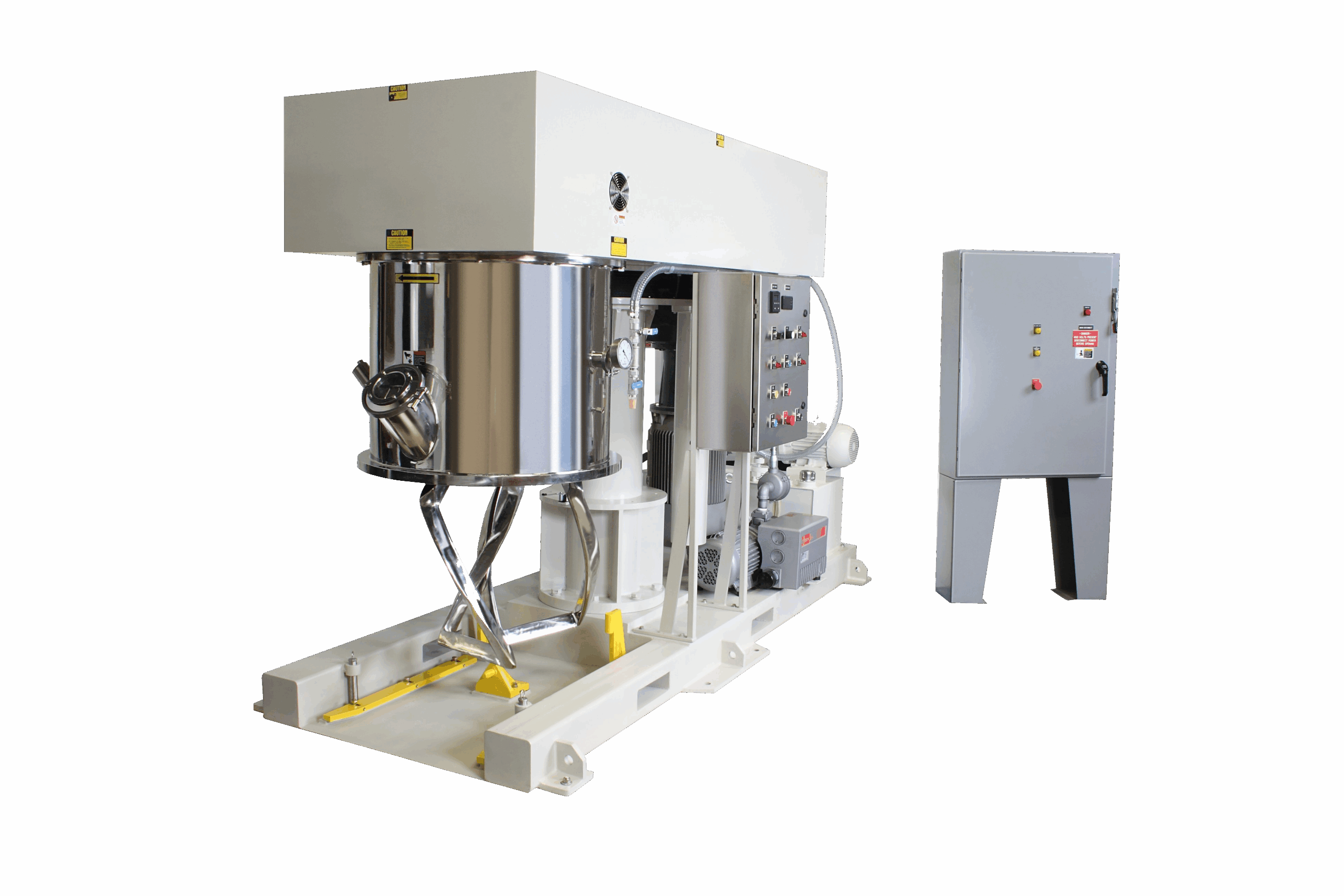

Our double planetary mixers feature two overlapping blades that mix materials with unparalleled efficiency. The unique planetary mixer design ensures thorough blending of both viscous and non-viscous products, making it suitable for a multitude of industrial needs. Unlike other mixers, the double planetary mixer combines the benefits of low or high-shear intensive mixing, delivering uniform homogenous results and effective dispersion.

Our Double Planetary Mixers are designed with durable construction, utilizing high-quality materials to ensure long-lasting performance and reliability. They offer versatile mixing capabilities, adept at handling a broad range of viscosities and materials—from thin liquids to thick pastes—making them highly flexible for various production processes. Precision engineering guarantees consistent results, delivering even mixing and blending every time, which enhances both product quality and production efficiency.

Jaygo’s Double Planetary Mixers

Jaygo’s Double Planetary Mixers are typically used in kneading, mixing, blending, dispersing, and drying applications. These mixers can be used with products of low to high viscosity, for a wide range of industries. Typical product viscosities range from 1 cps to approximately 2,000,000 centipoises.

Jaygo Double Planetary Mixers are designed to operate at high vacuum and feature jacketed construction (including insulation and sheathing), on the vessel sidewalls and bottom. Typical heating and cooling mediums include oil, water, steam, or glycol. The Planetary Mixers are designed to maintain working temperatures between 34 and 355°F, but can be built for higher temperature ranges when required.

Blade options include Quarter-Twist, Rectangular, Vertical Shaft, and Butterfly configurations, with optional High Speed Disperser Shaft and Blade assemblies utilizing a second drive.

Methods of product discharge include pressing product out with a Hydraulic Discharge Press, incorporation of a bottom discharge valve (ball, plug), or tilting the bowl to scoop or pour the contents out.

Planetary Mixers can be sized for laboratory use in 1, 5, and 10 liter volumes; pilot production with 20, 30, and 50 liter volumes; or full production with a 75 to 3000 liter volume range.

Applications

Jaygo’s double planetary mixers excel in numerous applications across different sectors:

- Industrial and Chemical: Ideal for window sealants, hot melt adhesives, silicone rubbers, pharmaceutical granulations, construction caulks, offset printing inks, epoxy resins, polyurethanes, ceramic pastes, metal powders, carbon pastes, conductive inks, food coatings, and granulations.

- Cosmetic and Pharmaceutical: Perfect for cosmetic creams, mascara, health care ointments, toothpaste, and gelatin.

- Specialty and Niche: Versatile for munitions, pyrotechnics, explosives, printing inks, viscous greases, grinding wheel compounds, dental compounds, solder pastes, castable inhibitors, acrylics, plastisols, roofing sealants, and battery paste.

Mix it Perfectly with Jaygo

Ready to experience the precision and efficiency of Jaygo Double Planetary Mixers? Contact us today to discuss your specific mixing needs and see how our advanced solutions can enhance your production process. We’re here to provide personalized recommendations and support, ensuring you find the perfect mixer for your application. Don’t settle for anything less than exceptional performance—reach out now to get started and see the difference our mixers can make.