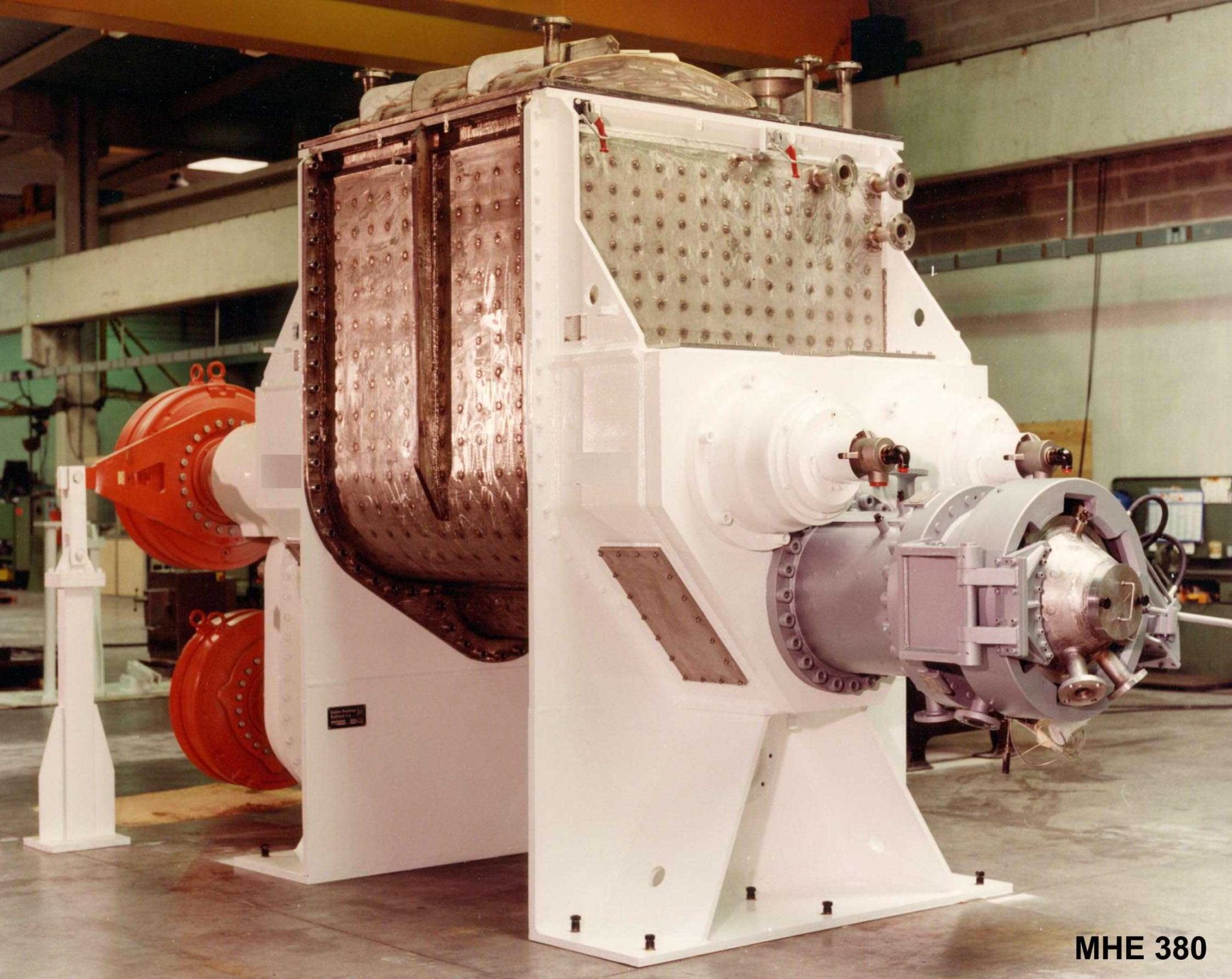

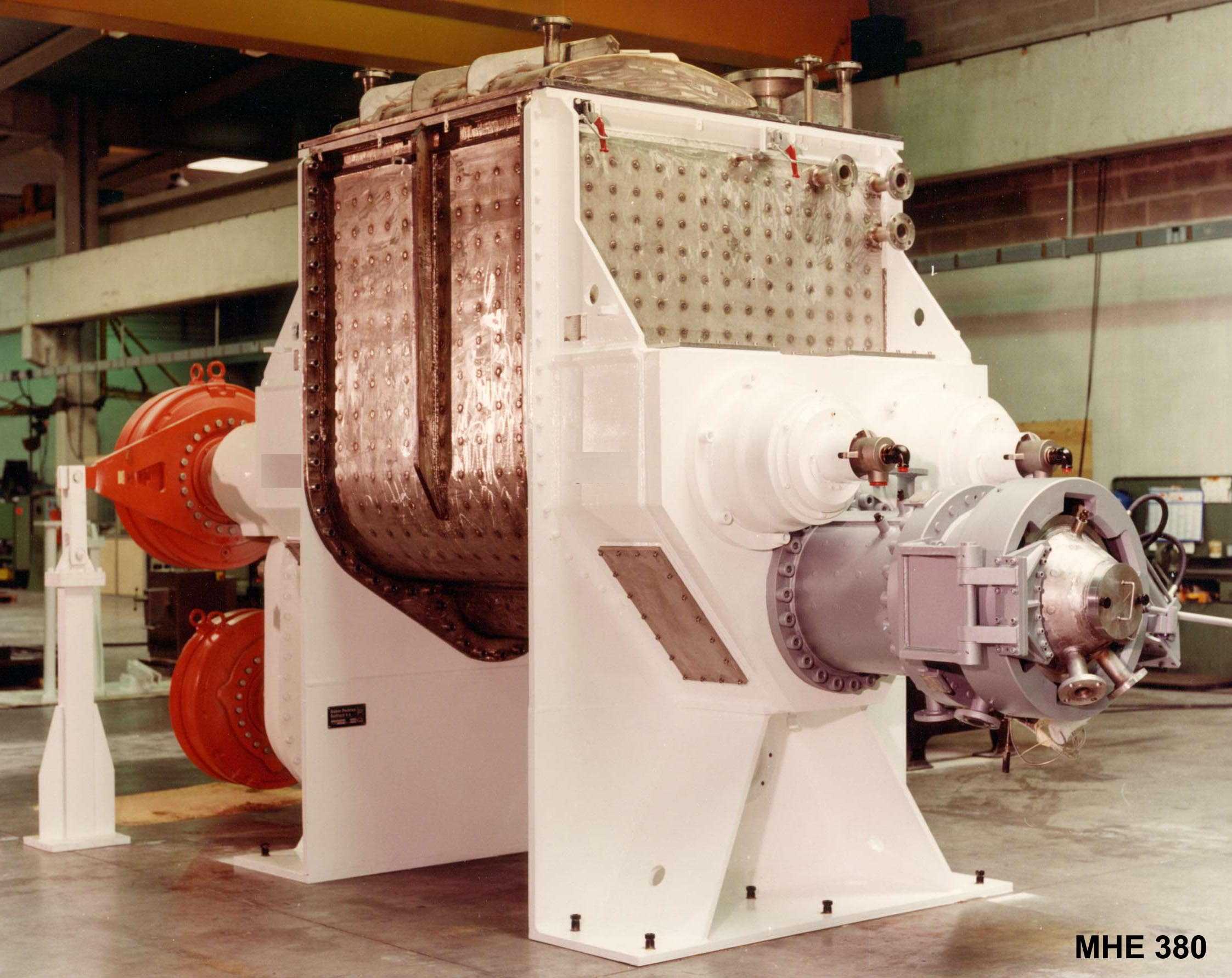

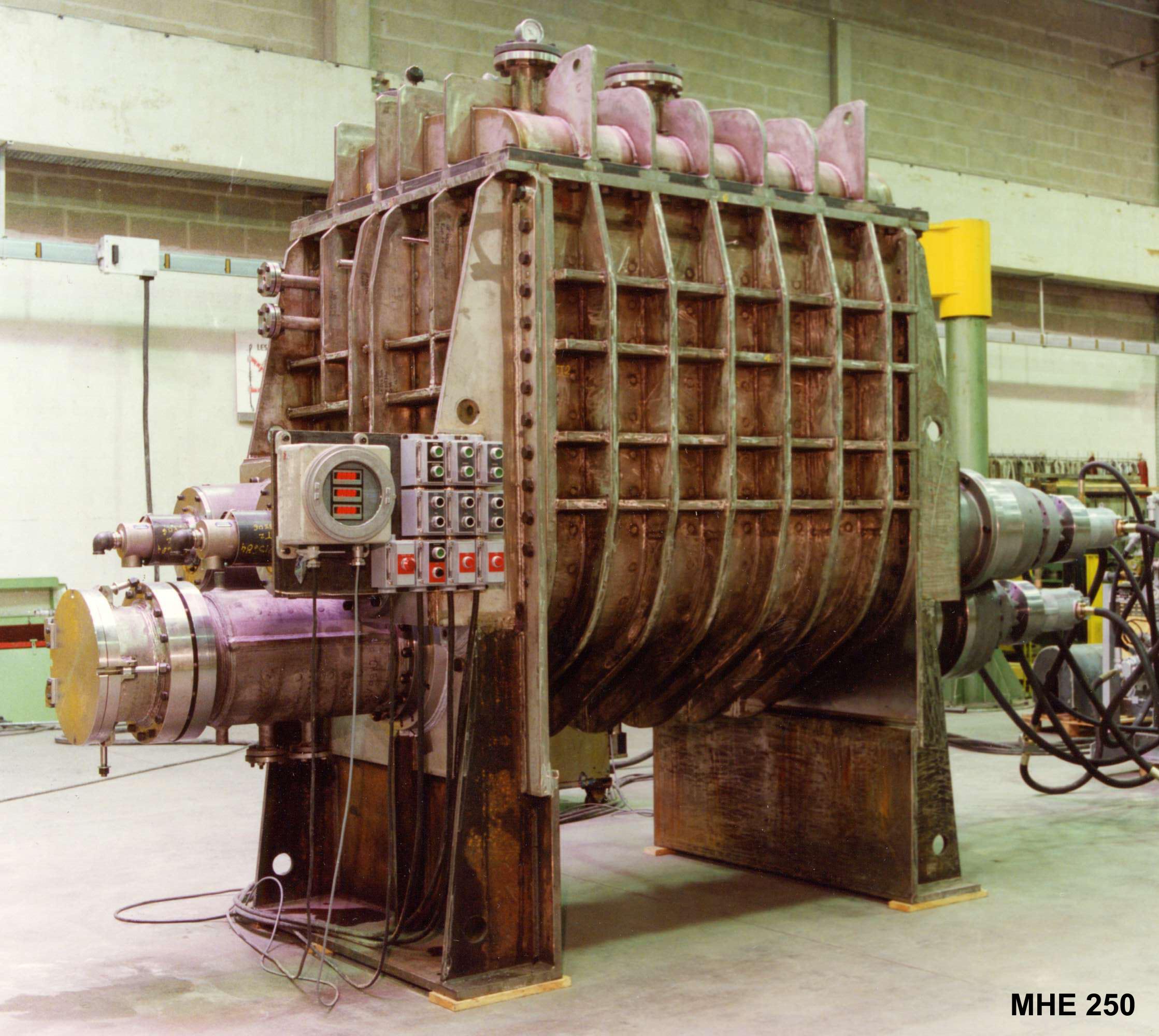

Double Arm Mixer Extruders

Mixing and Extrusion of High-Viscosity Products

Jaygo’s new Double Arm Mixer Extruders are robust, heavy-duty mixing machines designed for the production of high and very high viscosity products from 1,000,000 to 10,000,000 centipoises and beyond.

Jaygo mixers offer process flexibility, user friendliness, and easy to clean / maintain designs. The mixers are available in many sizes from 5 to 9000 liters working capacity and can offer a multitude of options.

Options:

- Mechanical or hydraulic drive system

- Jacketed mixing troughs or heating and cooling

- Designed for pressure, vacuum, or inert gas operation

- Remote operator control

- Specialized die heads / special extrusion fittings

- Automated operation of cover via hydraulic piston

- Cored blades of various design

Jaygo’s Mixer Extruders include an extrusion screw located in the bottom of the mixing chamber that operates in reverse during the mixing cycle, aiding the mixing blades slightly. The extrusion screw direction is then reversed after mixing, allowing the extrusion screw to discharge the product. Various shaped dies may be added to the end of the extrusion barrel, enhancing the versatility of the equipment.

Applications:

- Sealing compounds

- asphaltic derivatives

- mastics

- hot-melts

- floor coverings

- colorings

- rubber base

- master-batches

- chewing gum

- rubber compounds

- silicone

- lubricating greases

- dispersed pigments

- butyl

- gums and adhesives

- ceramic paste

- polyester compounds

- greasy inks

- pencil leads

- explosives

- powders to granulate

- PVC coatings

- resins soap

- brake linings

- carbon electrodes

- celluloid Bakelite

- battery paste

- polishing pastes