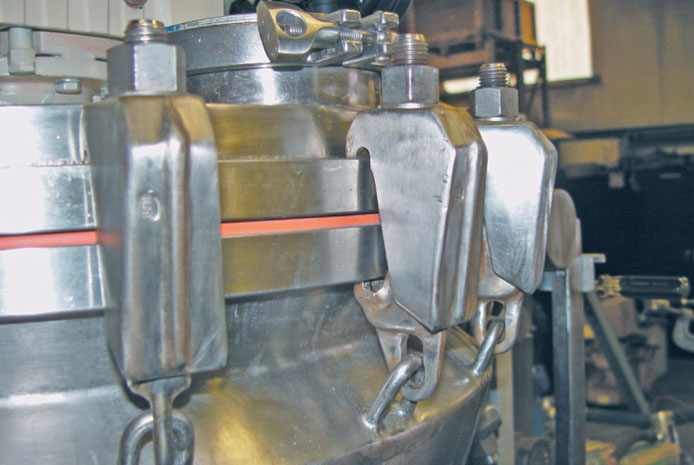

Pressure Vessel Clamps

The best way to clamp a pressure vessel, segmented screw or pipe

Jaygo carries a full line of pressure vessel clamps or segmented screw clamps designed to work with ASME code pressure vessels. Our quick release pressure vessel clamps eliminate the need to drill holes in the flange of the vessel, eliminating the stress concentrations at the bolt holes. Eliminating these stresses allows the flange to be thinner while providing the same closing strength.

These clamps are designed for compliance with all applicable ASME section VIII safety requirements and are approved for use by all major insurance companies. Not only do our quick release clamps save time and money in the design and fabrication of the vessel, they drastically reduce the time required to open and close the vessel, providing continual labor savings. At Jaygo, we specialize in customized solutions that help our clients increase safety and efficiency in their processing operations.

Our quick release pressure clamps are ideally suited for reactor vessels, pressure vessels, vacuum vessels, pressurized filter housings, mix vessels, Nutsche filters, centrifuges, and segmented screw.

- Hex head Nut

- Wing Nut

- Cap Nut

- T-Handle

Coating Options

- Zinc Plating

- Veralit Plating

- Electropolishing

- Pickling & Passivating

We operate a special test lab specifically for testing clamps by traceability number and can assist in choosing the appropriate size and strength of clamp for a given application. We carry stock on our most popular clamps to provide customers with expedited turnaround of the most commonly ordered clamp sizes and configurations.