Altern Mills – Batch Mills

Applications

- Pigmented Lipsticks

- Cosmetics

- Paints

- Inks

- Coatings

- Dyes

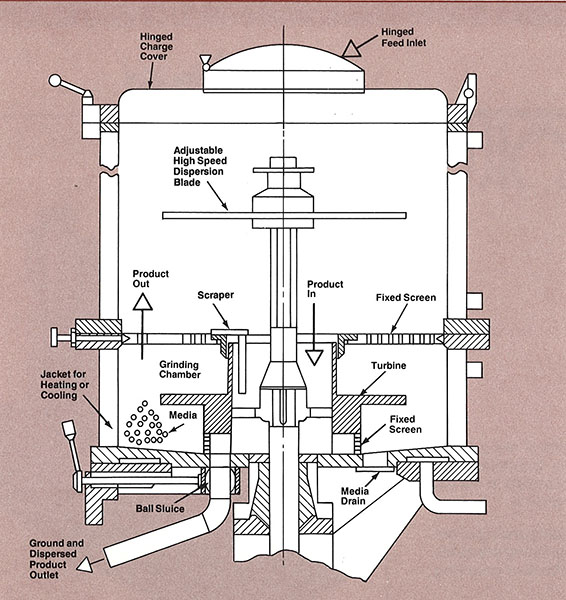

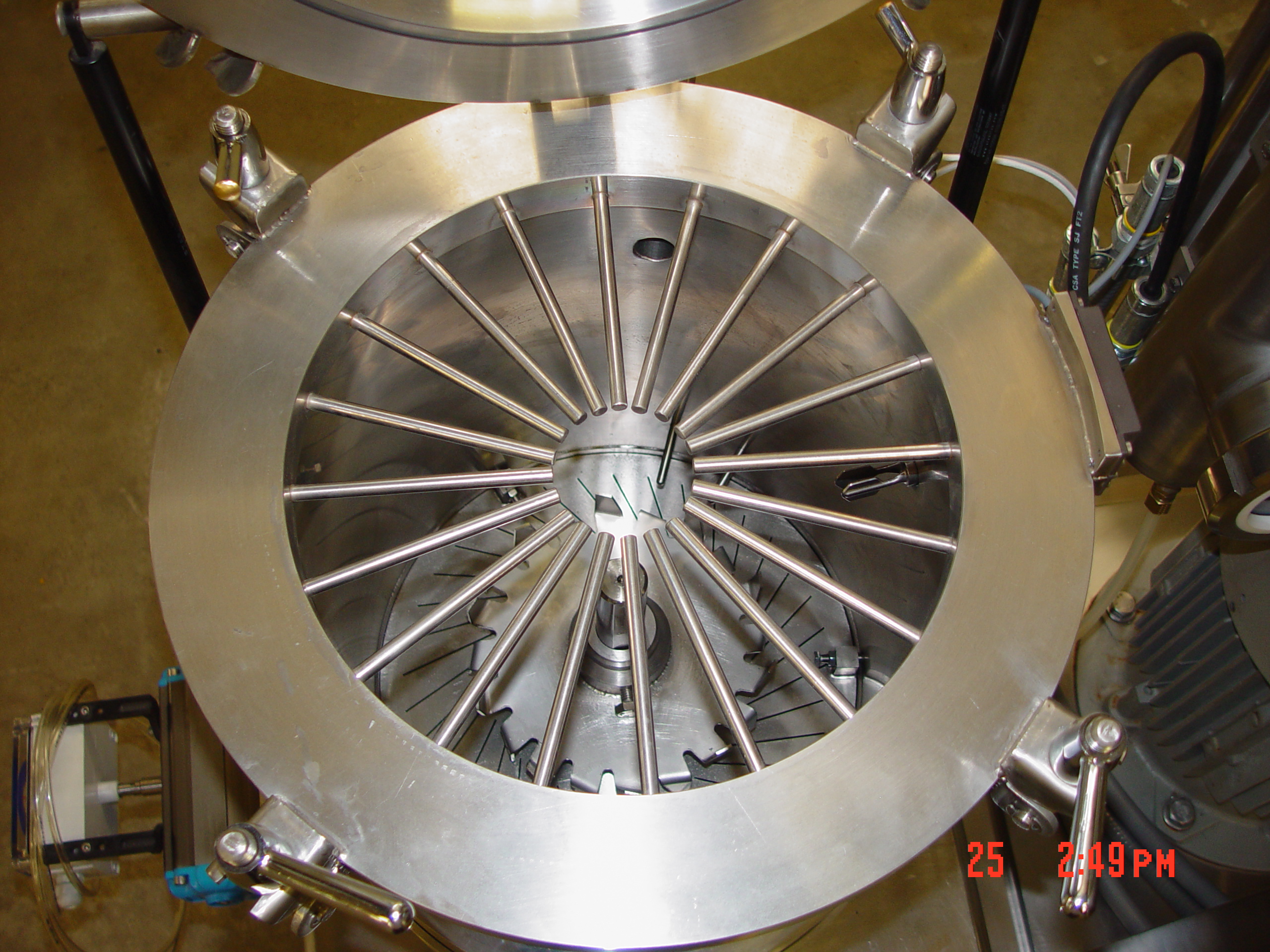

The Altern Mill is an environmentally safe, clean closed system that offers reproducible high quality dispersions. Years of technology advancement have resulted in a single unit processor for many “Ultra Fine” grinding operations. The Altern Mill combines the features of a High Speed Disperser and those of a Multi Media Mill into one State-of-the-Art Unit.

The unique grinding chamber reduces production time and decreases manufacturing costs.

Altern Mill Batch Mill Applications

The right choice for milling operations looking to achieve less product loss, less contamination and less exposure.

The mill is used in applications that are FDA approved. The mill is jacketed for heating/cooling allowing pre-melting of waxes and polymers and control of heat sensitive dispersions. Safety grating for loading of powder/liquid additions and safety interlocks are also included.

The unit can be supplied with

- Vacuum And Internal Pressure Capabilities

- A Cover With Fittings For Pressure And Vacuum Gauges

- Vent Valves

- Sight Glass

- Tri-clamp Fittings For Cip Spray Ball System

- Air Or Nitrogen Purging

- Removable Or Fixed Tri-clamp Discharge Nozzle

All internal corners are machined “rounded” for easy cleaning of pigment and also to aid dispersion by allowing media to “roll” into these “curves”. Depending on product viscosity, choice of (2) sizes of internal screens and various sizes of “Dragonite” grinding media are available.

Mill sizes range from 1 liter to 500 liters. Testing on the 8 liter lab unit is now available.