Understanding Double Arm, Sigma Blade, and Z Blade Mixers

In the vast world of industrial mixers, selecting the right equipment for your specific processing needs can be daunting. Among the most popular…

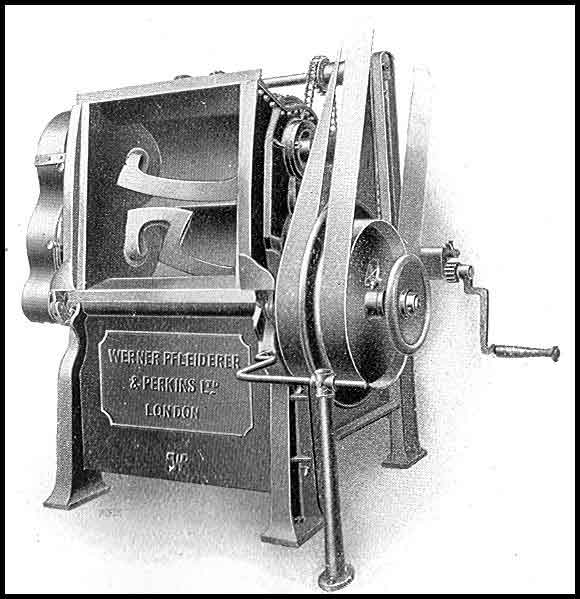

Baker Perkins Mixer

In an effort to dispel some confusion over the name Baker Perkins in reference to the Double Arm Mixers, we felt it beneficial to provide a short…

Pan Blender/Dryer model 1090

Working capacity 30-60 liters Total capacity 90 liters 304SS construction Vacuum design Jacketed cover, sidewalls, and bottom Low Speed Anchor…

Lab Vee Blender

Lab Vee Blender: 16 liters total capacity 316L SS, Intensifier Liquid Addition Safety Enclosure, Controls LIKE NEW…. $16,000

Double Cone Blender

Double Cone Blender: 100 liters total capacity 316L SS, Drive, SS Stand with Safety Gate LIKE NEW.$18,000

Ribbon Blender

Ribbon Blender 150 liters total capacity Up to 100 liters working capacity 304 SS construction, support frame on wheels Control panel with motor…

Rebuilt Double Arm Sigma Blade Mixer

Rebuilt Double Arm Sigma Blade Mixer 8 gallons total capacity ~5 gallons working capacity Stainless Steel product contact parts 5 HP drive motor,…

Rebuilt Double Arm Sigma Blade Mixer

Rebuilt Double Arm Sigma Blade Mixer – 8 gallons total capacity / ~5 gallons working capacity Stainless Steel product contact parts 5 HP drive motor…

Used -Jaygo Ribbon Blender – model: JRB-62.5

Jaygo Ribbon Blender –available for immediate shipment.Ribbon Blender model: JRB-62.5 Working Capacity: 62.5 cubic feet. Motor: 25 HP Discharge: 6”…

Longevity of Your Industrial Mixer

Tips for Improving the Longevity of Your Industrial Mixer Industrial mixers can be the heart and soul of any restaurant kitchen. They prevent…

The Remarkable Jaygo Double Arm Mixer Extruders

Revolutionizing IndustriesThe Remarkable Jaygo Double Arm Mixer Extruders In the dynamic landscape of industrial processes, there are moments when a…

Industrial Mixers And Blenders Used In Process Industries

A Legacy of Excellence: Tracing back to its roots, Jaygo’s commitment to quality and efficiency has always been evident. Since introducing its…

Jaygo Inc’s Altern Mill – Batch Mills

Elevate your milling operations to unparalleled efficiency and precision utilizing Jaygo Inc’s state-of-the-art Altern Mill and Batch Mills. Our premium products are meticulously crafted to yield exceptional outcomes, fostering heightened efficiency, elevated product quality, unmatched versatility, and seamless adaptability. By embracing Jaygo Inc’s advanced technologies, expect substantial cost savings, unwavering expert guidance, and the profound advantages derived from decades of industry expertise. Entrust your milling requisites to the pioneering leader and connect with our in-house engineers today to explore our comprehensive selection. Experience a millennial shift in your milling process with Jaygo Inc’s revolutionary solutions.

Industrial Mixer Maintenance Tips

Industrial mixers require proper and regular maintenance and cleaning to enhance their longevity and optimal performance. Read our tips in this blog.

What to Consider before You Purchase a Mixer for Your Business

What to Consider Before You Purchase a Mixer for Your Business

What You Need to Consider before You Choose a Mixing Machine

What to Consider before You Purchase a Mixer for Your Business Mixing equipment is an essential component in many industries that require…

6 Tips for Process Equipment Maintenance

6 Tips for Process Equipment Maintenance Manufacturing equipment is an integral part of the production…

Failing Ball Segment Valve | Jaygo Incorporated

Signs of a Failing Ball Segment Valve Ball segment valves are critical in various industries,…

Renting Industrial Equipment | Jaygo Incorporated

Tips to Consider When Renting Industrial Processing Equipment As an industrial plant, you may require machinery or equipment to be able to…

Refurbished Industrial Equipment | Jaygo Incorporated

5 Factors to Consider When Purchasing Refurbished Industrial Equipment You always have the option to buy new or refurbished equipment for…