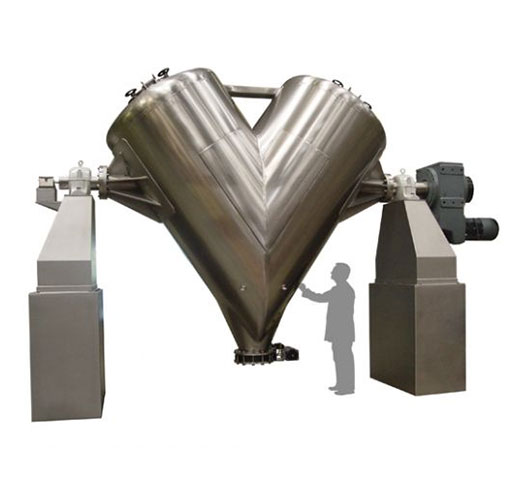

Vee & Double Cone Blenders

Jaygo Vee Blenders and Double Cone Blenders provide gentle high-flow mixing for solids/solids blends Designed to mix in a proportion of up to 1:100.000 with the possibility of using an intensifier bar to enhance the mixture, and solids/liquids in powder or granulate form with different specific weights. Due to the characteristic shapes formed by two normally identical sections joined at a specific angle, axial flows are created inside which separate and join the product to be mixed, and which together with the radial action of the mixture, results in a rapid and uniform mix Discharge is via an outlet at the base of the two cylinders, where a butterfly valve is fitted with lever control or pneumatic activator.

Jaygo’s Industrial Process Blenders

Advantages of the Vee or Double Cone Blende

- Gentle mixing process without deforming the particles or creating fines

- Complete discharge via gravity. Construction is free of dead-spots, corners, or angles where product can accumulate.

- Inlets are fitted with dust-tight covers

- Low energy consumption compared to other mixing systems.

- High profitability due to the high production capacity, mixing quality, low energy consumption and minimum maintenance.