Sampling Valves for Solids and Slurries

An efficient way to take samples of powders, granulators, parts, and liquids

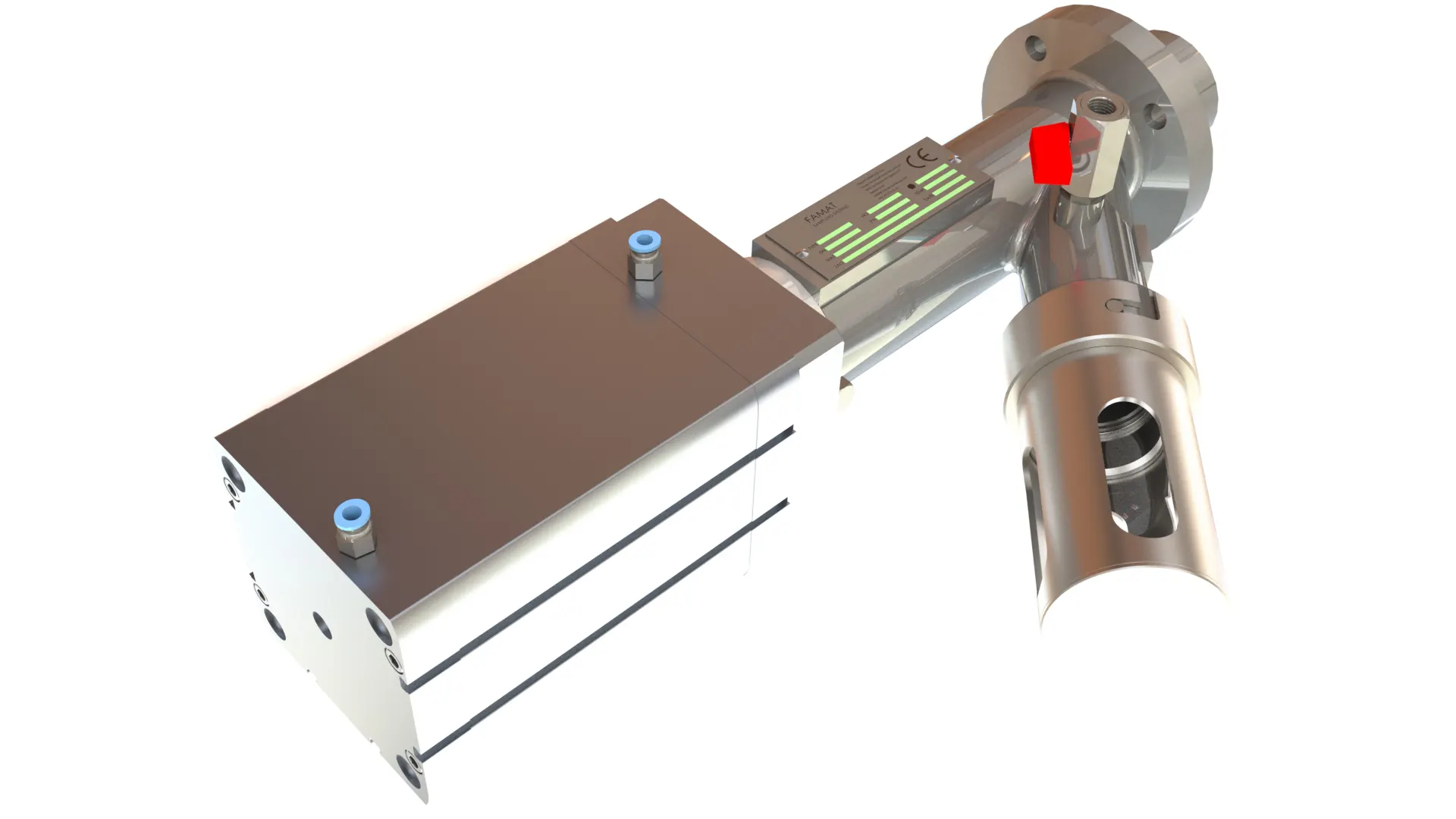

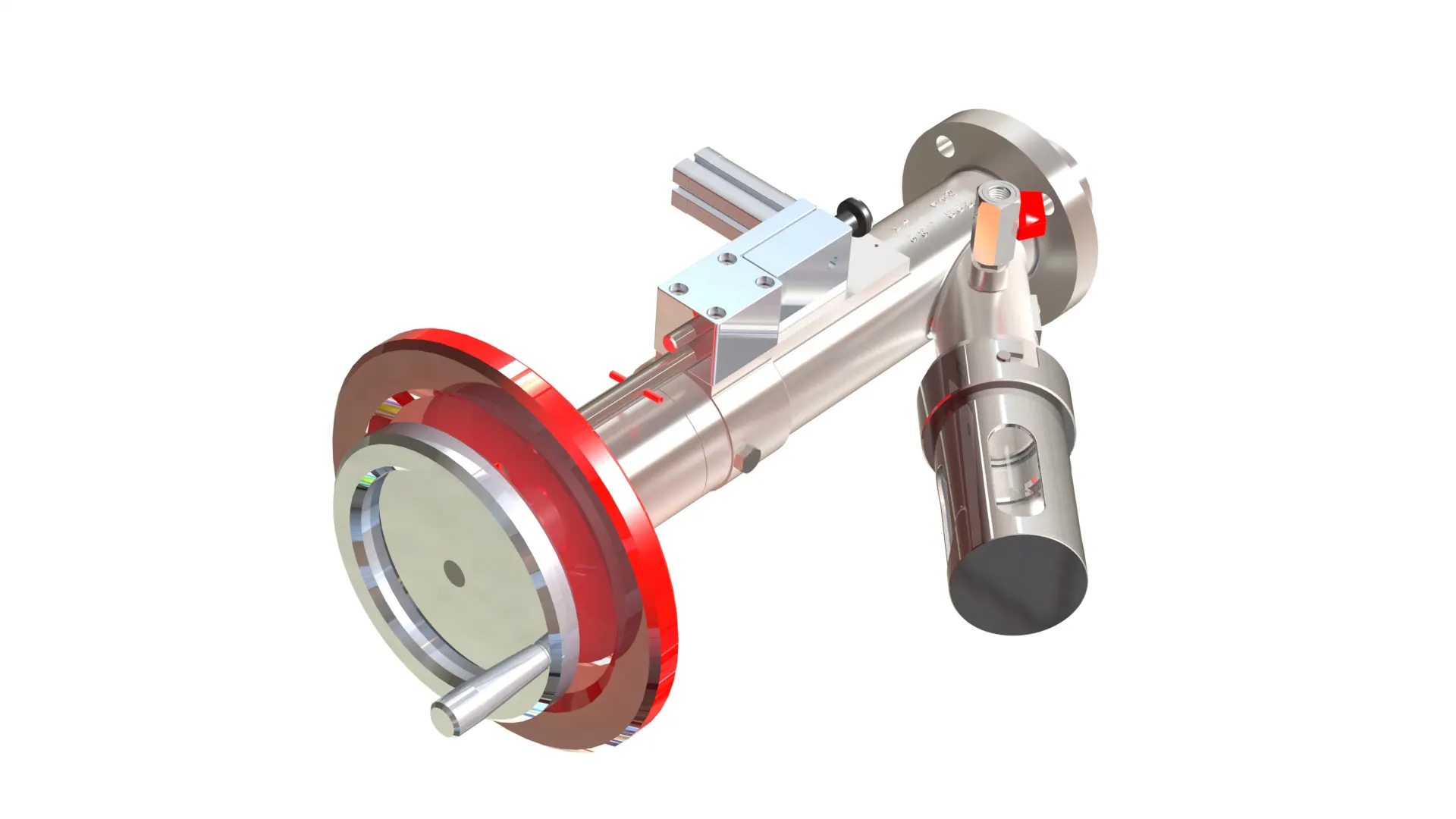

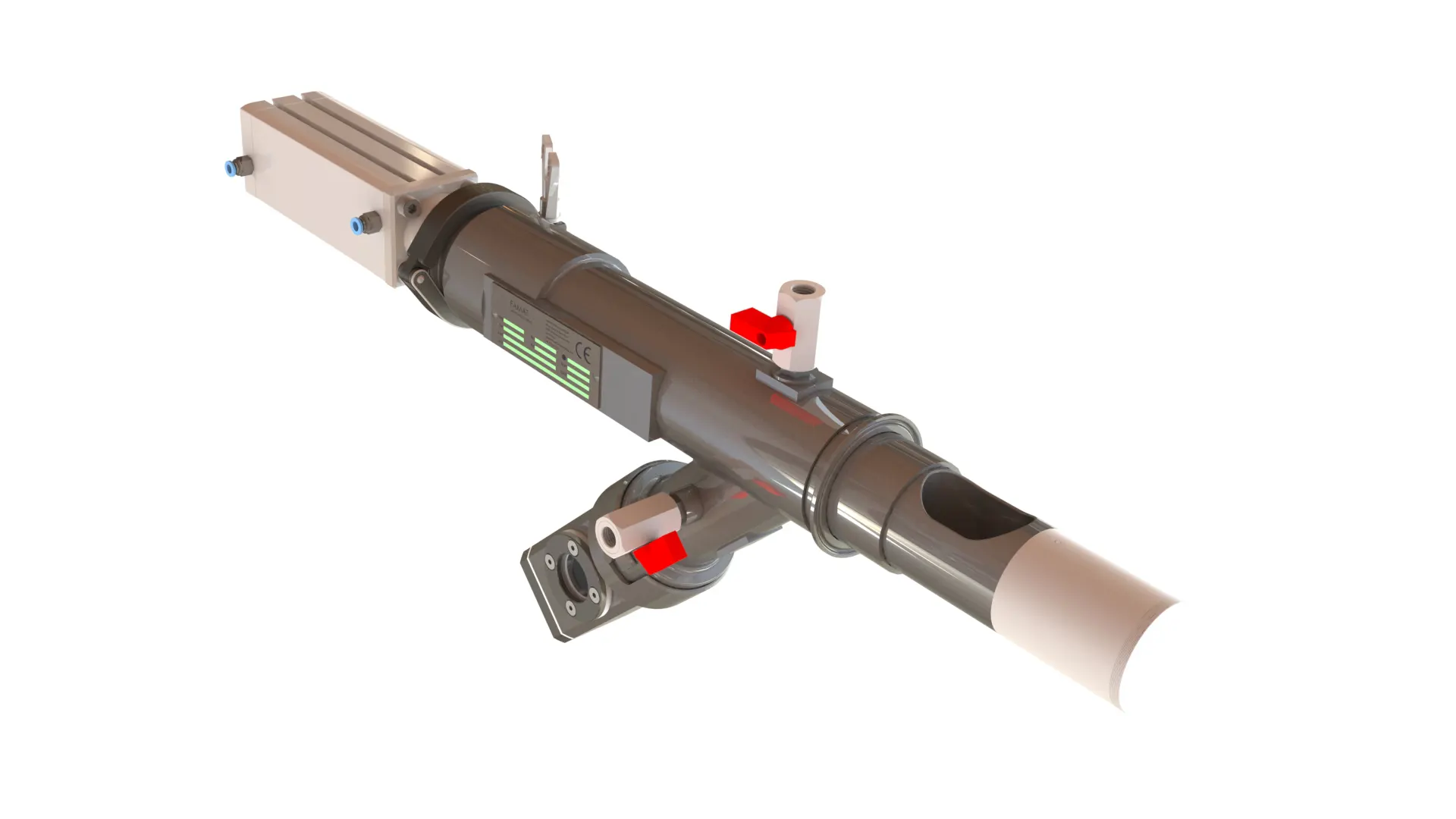

The Sampling valve allows taking samples of chemicals or pharmaceuticals (liquids, powders, suspensions) from process vessels and reactors. The sampling can be made during the process, under vacuum or pressure up to 10 bar. This means that the pressure or vacuum level in the processing system will not be disturbed. Sample valves are most commonly used to simplify the extraction of samples from or the injection into tanks, reactors, or pipelines and allow for trouble-free service over long periods of time. Typical applications are:

- Vacuum dryers and mixers

- Reactors or vessels under pressure or vacuum

When choosing a Sampling Valve, different factors have to be considered:

- The material, pressure and temperature rating, gaskets, size and position of the valve according to the pipe specification of the plant.

- The handle or actuator type according to the position (reach) of the valve and depending on the chemical to sample (i.e. if the product contains solid particle or not)

- The receptacle to store the sample for transportation (bottles, container, bag, piston injector or syringe)

When sampling hazardous chemicals or deadly substances, it is extremely important that the operator is not exposed to toxic fumes or vapors. These can fatally harm people and should they be released into the atmosphere, they will pollute the environment