Understanding Double Arm, Sigma Blade, and Z Blade Mixers: A Comprehensive Guide.

In the vast world of industrial mixers, selecting the right equipment for your specific processing needs can be daunting. Among the most popular choices for high-viscosity mixing are Double Arm Mixers, Sigma Blade Mixers, and Z Blade Mixers. Though these mixers share some similarities, understanding their differences, as well as their respective pros and cons, is crucial for making an informed decision. This blog post aims to shed light on these aspects, guiding businesses in selecting their mixing needs.

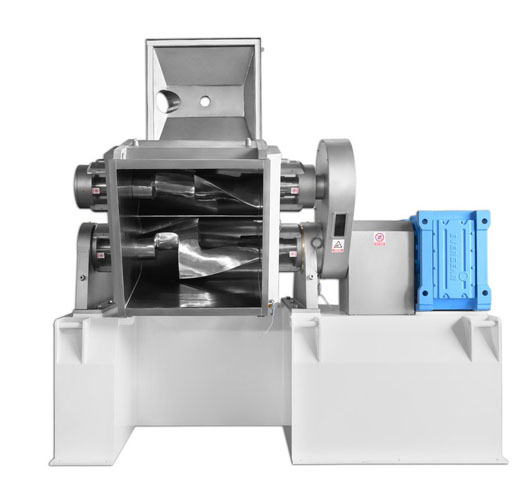

Double Arm Mixers

Double-arm mixers are characterized by two horizontally aligned arms that rotate in opposite directions. They are versatile machines used in various applications, from dough mixing to metal powders.

Pros:

- Versatility: Can handle a wide range of materials, including high-viscosity compounds.

- Efficient Mixing: The counter-rotating arms provide excellent mixing capabilities, ensuring uniformity.

- Customizable: They can be equipped with different blades (e.g., sigma, paddle) for specific mixing needs.

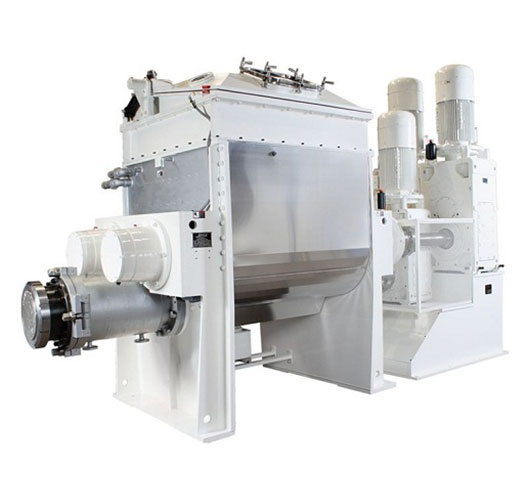

Sigma Blade Mixers

Sigma Blade Mixers, often considered a subtype of double arm mixers, utilize two Z-shaped blades that rotate to mix materials. They are especially favored for mixing very viscous materials.

Pros:

- Optimal for Viscous Materials: Excellently mixes heavy and sticky substances like adhesives, sealants, and dough.

- Shearing Action: The sigma blades provide a shearing action that helps in breaking down materials and ensuring a homogenous mix.

- Heat Control: Can be designed with jacketed vessels for heating or cooling, which is essential for temperature-sensitive materials.

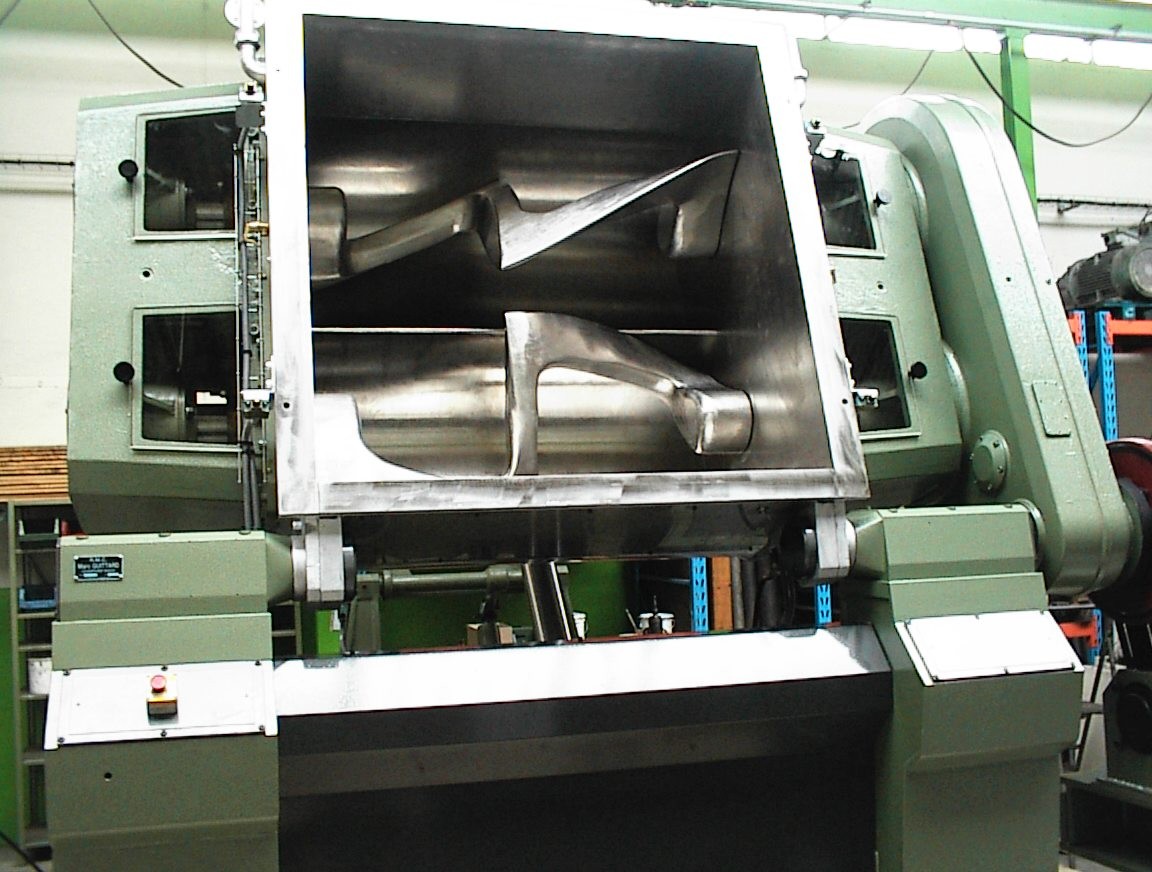

Z Blade Mixers

Z Blade Mixers are very similar to Sigma Blade Mixers in terms of the blade design and are also considered a variant of the double arm mixer. The difference lies mainly in the specific blade design and mixing action.

Pros:

- Efficient Kneading: The Z-shaped blades provide an excellent kneading action, making them suitable for tough, dense mixtures.

- Versatility: Good for a range of high-viscosity materials, from rubber to heavy pastes.

- Temperature Control: Like Sigma mixers, they can be equipped with temperature control features for precise processing.

- Space Requirements: The design and operation of Z blade mixers require more space than some other types of mixers.

Conclusion

When choosing between Double Arm, Sigma Blade, and Z Blade Mixers, the decision largely hinges on the specific characteristics of the material to be mixed, the desired outcome, and operational considerations such as space and maintenance capabilities. Double Arm Mixers offer versatility and are adaptable to a wide range of materials. Sigma Blade Mixers are the go-to for very viscous, sticky materials requiring shear, whereas Z Blade Mixers excel in kneading and processing tough, dense mixtures.

Each type of mixer has its unique set of advantages and drawbacks, making it crucial for businesses to assess their needs carefully before making a selection. Consulting with experts and possibly conducting material tests can further aid in choosing the most suitable mixer for your application, ensuring efficiency, quality, and satisfaction in your mixing processes.

For more insights and guidance on selecting the right industrial mixing equipment for your needs, stay tuned to JaygoInc.com.